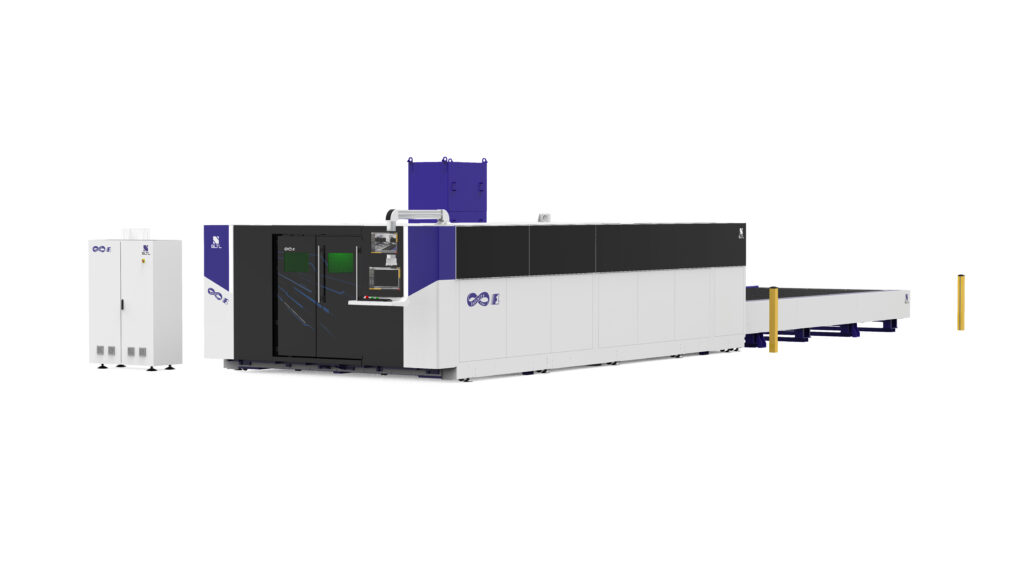

Fiber lasers are at the forefront of modern manufacturing, offering unparalleled precision, efficiency, and versatility. SLTL Group, a pioneer in laser solutions, has been instrumental in driving the adoption of fiber lasers across various industries. This blog explores the transformative trends and innovations in the fiber laser market, highlighting how SLTL Group is leading the charge.

Overview of Fiber Laser Technology

Fiber lasers generate laser beams through optical fibers doped with rare-earth elements like ytterbium. These lasers have a reputation for delivering high beam quality, efficiency, and low maintenance requirements. In comparison to traditional CO2 and solid-state lasers, fiber lasers offer superior performance and flexibility in various applications. Moreover, they are more cost-effective and require less maintenance. SLTL Group has been at the forefront of developing advanced fiber laser systems that cater to the evolving needs of modern manufacturing.

Key Trends in the Fiber Laser Market

- Increasing Demand for Precision and Efficiency

In manufacturing, precision and efficiency are crucial. Fiber lasers excel in delivering high-precision cuts and welds, which are essential for industries where accuracy is paramount. SLTL Group has designed fiber laser solutions to meet these demands, ensuring consistent performance and high-quality output. Consequently, their innovative systems provide manufacturers with the tools they need to achieve precision and efficiency in their production processes.

- Adoption in Various Industries

Fiber lasers have found applications in numerous industries, including automotive, aerospace, electronics, and medical devices. For example, SLTL Group uses its fiber laser machines to cut and weld car parts with unmatched precision in the automotive sector. In the aerospace industry, the company utilizes its lasers to drill holes in engine components. Additionally, the electronics industry benefits from SLTL Group’s solutions for tasks like cutting printed circuit boards and marking electronic components. Their versatile machines are tailored to meet the specific needs of each industry.

- Advancements in Fiber Laser Technology

The fiber laser market is witnessing rapid technological advancements, and SLTL Group is at the forefront of these innovations. Their development of high-power fiber lasers and single-mode fiber lasers is pushing the boundaries of what these machines can achieve. As a result, these advancements enhance performance and capabilities, enabling SLTL Group to provide solutions that tackle more demanding applications with greater efficiency.

- Growth in the Global Market

The global fiber laser market is experiencing robust growth, driven by the increasing demand for advanced manufacturing technologies. Manufacturers worldwide have adopted SLTL Group’s innovative products, making them a key player in this growth. The rise in industrialization and the need for efficient production processes are primary drivers of this growth, and SLTL Group’s cutting-edge solutions are perfectly positioned to meet these demands.

Innovations Driving the Fiber Laser Market

- Ultra-High Power Fiber Lasers

SLTL Group’s recent developments in ultra-high power fiber lasers have expanded their application range. These lasers deliver power levels previously unattainable with conventional lasers, making them ideal for heavy-duty applications such as cutting thick metal sheets. Consequently, SLTL Group’s ultra-high power fiber lasers provide intense and focused energy, ensuring precise and efficient cutting.

- Integration with Automation and AI

SLTL Group is revolutionizing manufacturing processes by integrating fiber lasers with automation and AI technologies. Their smart manufacturing systems can perform complex tasks with minimal human intervention, thereby enhancing productivity and ensuring higher quality and consistency. For example, SLTL Group’s automated laser cutting systems adjust parameters in real-time based on feedback from AI algorithms, providing unparalleled precision and efficiency.

- Environmental and Cost Benefits

Fiber lasers are known for their energy efficiency, consuming less power compared to traditional lasers. SLTL Group’s fiber laser solutions are designed to reduce operational costs and minimize environmental impact. Additionally, their lasers have fewer consumables and require less maintenance, leading to significant long-term cost savings for manufacturers. SLTL Group’s commitment to sustainability is evident in their innovative and energy-efficient products.

Challenges and Future Outlook

Despite their many advantages, fiber lasers face challenges such as high initial costs and the need for skilled operators. However, SLTL Group is addressing these issues through ongoing research and development, making their fiber lasers more accessible and easier to operate. The future of the fiber laser market looks promising, with potential breakthroughs in areas like beam quality enhancement and further integration with smart technologies. SLTL Group is poised to lead the way in these advancements, ensuring their solutions remain at the cutting edge of the industry.

Conclusion

Fiber lasers are revolutionizing modern manufacturing, and SLTL Group is at the forefront of this transformation. Their precision, efficiency, and versatility make them indispensable in various industrial applications. As technological advancements continue to push the boundaries, SLTL Group’s innovative fiber laser solutions are set to drive the future of manufacturing. Embracing these trends and innovations will be key for manufacturers looking to stay competitive in the evolving landscape.