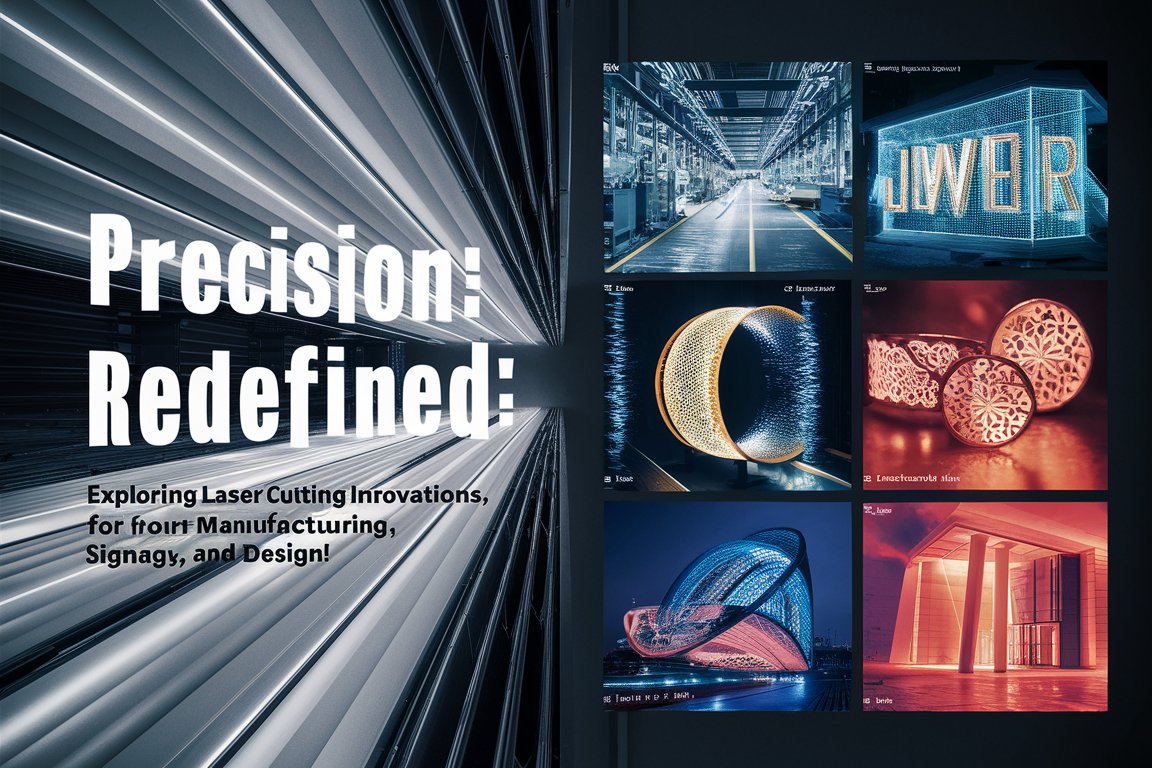

Laser cutting technology has revolutionized the manufacturing and fabrication industries over the past few decades. From its humble beginnings as a niche application, laser cutting has evolved into a mainstream method for precision cutting and engraving across a wide range of materials. This blog explores the recent advancements in laser cutting technology, highlighting innovations, applications, and the benefits that businesses can gain from adopting these cutting-edge techniques.

What is Laser Cutting?

Laser cutting uses a high-powered laser beam to cut or engrave materials with incredible precision. The laser targets the material, causing it to melt, burn, or vaporize, resulting in a precise and neat cut. This method works on various materials, including metals, plastics, wood, and glass, making it a versatile tool for many industries.

Recent Innovations in Laser Cutting Technology

- Fiber Laser Technology Fiber lasers represent a major breakthrough in laser cutting technology. Unlike traditional CO2 lasers, fiber lasers use a solid-state medium and are more efficient, offering faster cutting speeds and improved energy consumption. Fiber lasers are well-suited for industries like aerospace, automotive, and metal fabrication due to their ability to cut through thicker materials with increased precision.

- Automation and Robotics The integration of automation and robotics into laser cutting systems has greatly enhanced productivity and efficiency. Automated laser cutting machines can run non-stop, lowering labor expenses and reducing the occurrence of human errors. Additionally, robotic arms can manipulate the workpiece, allowing for complex geometries and multi-axis cutting that would be challenging to achieve manually.

- Advanced Software Solutions Recent advancements in software have transformed how laser cutting machines are programmed and operated. Modern laser cutting systems come equipped with sophisticated software that allows for easier design, simulation, and optimization of cutting paths. This software can analyze material properties and suggest the best cutting parameters, resulting in improved accuracy and reduced waste.

- Hybrid Laser Technology Hybrid laser technology combines laser cutting with other methods, such as plasma or waterjet cutting. This method provides increased flexibility and the capability to trim a broader variety of materials and thicknesses. Hybrid systems can switch between laser cutting and other methods, optimizing the cutting process based on the specific requirements of the job.

- Increased Material Compatibility Recent advancements have expanded the range of materials that can be effectively cut using laser technology. Innovations in laser systems have made it possible to cut reflective materials, such as copper and brass, which were previously challenging to work with. This increased compatibility opens up new opportunities for industries that rely on these materials.

Applications of Laser Cutting Technology

The versatility of laser cutting technology has led to its adoption across various industries. Some notable applications include:

- Manufacturing: Creating precise components and parts for machinery, vehicles, and electronics.

- Signage and Displays: Creating intricate designs in signage and displays, allowing for customized branding and marketing materials.

- Jewelry Making: Creating intricate designs and personalized pieces, enhancing the artistry of jewelry.

- Architecture and Interior Design: Producing unique aesthetics and functional solutions with laser-cut panels and decorative elements.

Benefits of Laser Cutting Technology

- Precision and Quality of Cuts Laser cutting technology excels in delivering high precision and exceptional cut quality. The laser beam can be focused to a very fine point, allowing for intricate designs and tight tolerances. This precision ensures smooth and clean edges, reducing the need for secondary finishing processes. For example, in the aerospace industry, where exact measurements are crucial, laser cutting ensures parts fit perfectly without additional adjustments.

- Cost-Effectiveness While the initial investment in laser cutting technology may be substantial, the long-term cost savings are significant. Laser cutting minimizes material waste by producing highly accurate cuts, which translates to lower material costs. In the automotive industry, the ability to cut complex shapes without extensive tooling reduces production costs and accelerates the manufacturing process, leading to overall cost efficiency.

- Speed and Efficiency Laser cutting machines can operate at high speeds, drastically reducing production times. The automation of laser cutting processes allows for continuous operation, further enhancing efficiency. For industries requiring rapid turnaround times, such as electronics manufacturing, laser cutting ensures that large production runs are completed swiftly without compromising quality.

- Environmentally Friendly Laser cutting technology is considered more environmentally friendly than traditional cutting methods. The precision of laser cutting reduces material waste, and the energy consumption of modern laser systems is lower than that of conventional cutting machines. Additionally, laser cutting produces minimal pollutants. In the context of the metal fabrication industry, this means a cleaner and more sustainable production process.

- Customization and Flexibility Laser cutting technology allows for easy customization and flexibility in production. Designers can quickly modify designs and produce unique pieces without extensive retooling. This adaptability is particularly valuable in industries like fashion and interior design, where customer preferences and trends change rapidly. For instance, custom decorative panels can be quickly produced to meet specific design requirements.

Conclusion

Recent advancements in laser cutting technology have transformed the landscape of manufacturing and fabrication. From fiber lasers and automation to advanced software solutions and increased material compatibility, these innovations have made laser cutting more efficient, precise, and versatile than ever before. As businesses continue to seek ways to improve productivity and reduce costs, laser cutting technology will undoubtedly play a crucial role in shaping the future of manufacturing.

By embracing these advancements, companies can leverage the benefits of laser cutting to stay competitive in an ever-evolving market. Whether for large-scale production or intricate custom projects, laser cutting technology offers a wealth of opportunities for innovation and growth. For more information on laser cutting solutions, visit SLTL or explore SLTL’s product offerings.