In the ever-evolving field of renewable energy, thin-film solar cells present a promising solution due to their potential for cost-effective and versatile applications. A critical aspect of their manufacturing process is laser scribing. It’s a technique that significantly enhances the efficiency and quality of these solar cells. SLTL Group, a leader in laser technology, offers cutting-edge solutions that revolutionize this manufacturing process.

What is Laser Scribing?

Laser scribing involves using a focused laser beam to create precise lines or patterns on the surface of thin-film solar cells. This process is essential for defining different layers and improving the electrical isolation between cells, thereby enhancing their performance.

Key Benefits of Laser Scribing

- Precision and Accuracy: Laser scribing provides exceptional precision, allowing manufacturers to create intricate patterns crucial for high-efficiency solar cells. This high level of accuracy is vital in ensuring that each cell operates at its maximum potential, thereby increasing the overall efficiency of the solar module.

- Minimal Material Waste: As a non-contact process, laser scribing reduces material waste and increases production yield. The laser’s ability to precisely target specific areas without affecting the surrounding material ensures that the thin-film layers remain intact, reducing wastage and saving costs.

- High Speed: The process significantly speeds up compared to traditional scribing methods, enabling higher throughput and reducing production costs. This speed maintains quality, as the laser’s precision ensures that each cell is crafted to the highest standards.

- Flexibility: You can easily adjust laser systems to accommodate different materials and thicknesses, making them versatile for various thin-film technologies. This adaptability means that manufacturers can use the same laser system for multiple types of thin-film solar cells, from cadmium telluride (CdTe) to copper indium gallium selenide (CIGS).

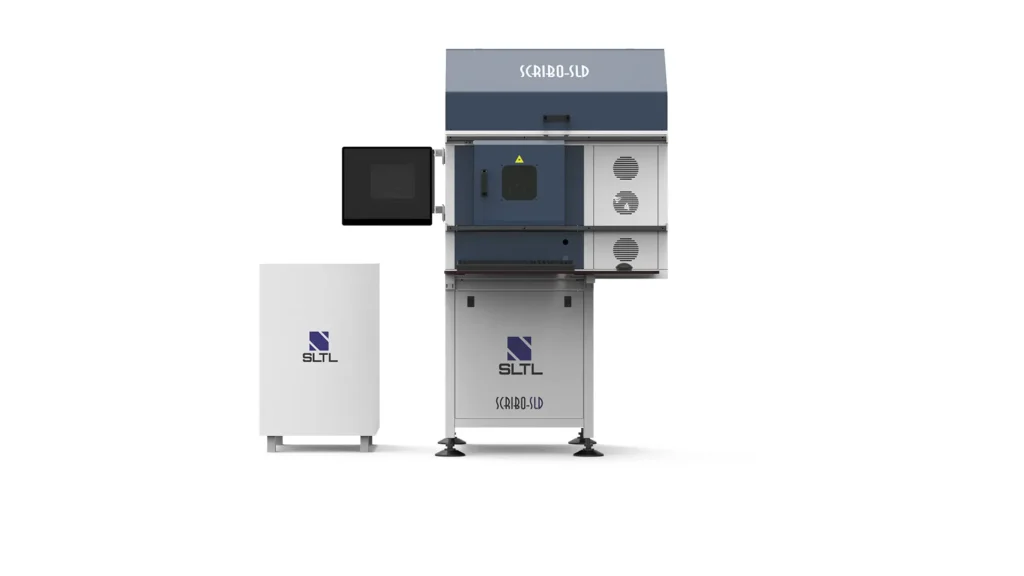

SLTL Group’s Cutting-Edge Solutions

SLTL Group has been at the forefront of laser technology innovation. It provides state-of-the-art laser scribing solutions tailored to the specific needs of thin-film solar cell manufacturers.

Advanced Laser Systems

SLTL Group’s laser systems boast several advanced features:

- High Precision: With advanced beam control and focusing systems, SLTL’s lasers achieve exceptional precision, essential for intricate solar cell patterns. These systems ensure that each scribe is performed with micron-level accuracy, which is critical for maintaining the integrity of the thin-film layers.

- Automated Processes: These systems come with automation capabilities, reducing the need for manual intervention and ensuring consistent quality. Automation also allows for continuous operation, further increasing production efficiency and reducing the likelihood of human error.

- Custom Solutions: SLTL Group offers tailored solutions to meet unique manufacturing requirements, ensuring optimal performance. Whether a manufacturer requires a specific wavelength or power level, SLTL can customize their laser systems to meet these needs, providing a bespoke solution that enhances productivity.

Impact on Thin-Film Solar Cell Manufacturing

The integration of laser scribing in thin-film solar cell manufacturing has led to significant improvements in efficiency and cost-effectiveness. By enabling precise patterning and reducing material waste, laser scribing enhances overall yield and performance.

Real-World Applications

Several case studies highlight the benefits of SLTL Group’s laser systems:

- Increased Efficiency: A manufacturer experienced a 20% increase in efficiency after adopting SLTL’s laser scribing system, showcasing the technique’s potential to enhance solar cell performance. This boost in efficiency translates to more energy generated per unit area, making the solar cells more competitive in the market.

- Cost Reduction: Another company reported a 15% reduction in production costs due to the high speed and precision of SLTL’s lasers, demonstrating the cost-saving benefits of this technology. The reduction in costs is primarily due to the decrease in material wastage and the faster production times, allowing the company to produce more cells in a shorter period.

- Improved Product Quality: The enhanced precision of laser scribing resulted in higher-quality solar cells with fewer defects, leading to better performance and longevity. High-quality cells are less likely to suffer from issues such as micro-cracks or poor electrical connections, which can degrade performance over time.

Additional Benefits

Beyond these case studies, laser scribing offers other significant advantages:

- Scalability: Laser scribing systems can be easily scaled up to accommodate increased production demands. This scalability ensures that manufacturers can ramp up their production without the need for significant additional investment.

- Environmental Impact: By reducing material waste, laser scribing contributes to more sustainable manufacturing processes. This environmental benefit aligns with the broader goals of the renewable energy industry, which aims to minimize its carbon footprint.

- Enhanced Durability: Laser-scribed solar cells often exhibit enhanced durability due to the precise and clean cuts made by the laser. This durability is crucial for solar panels that need to withstand harsh environmental conditions over their lifespan.

Future Prospects

As the demand for renewable energy grows, the need for efficient and cost-effective manufacturing processes for solar cells becomes increasingly important. Laser scribing is poised to play a critical role in the future of thin-film solar cell production.

Innovations on the Horizon

SLTL Group continues to explore new laser technologies and applications to further enhance the efficiency of thin-film solar cell manufacturing:

- Higher Power Lasers: Developing higher power lasers for even faster scribing without compromising precision. These high-power lasers can increase production speed while maintaining the accuracy required for thin-film solar cells.

- Enhanced Automation: Integrating more sophisticated automation systems to further reduce manual intervention and increase throughput. Advanced automation technologies, such as machine learning algorithms, can optimize the scribing process in real-time, ensuring consistent quality and efficiency.

- New Materials: Adapting laser systems to work with emerging thin-film materials, expanding potential applications. As new materials are developed for solar cells, such as perovskites, laser scribing systems will need to evolve to handle these innovative materials effectively.

Research and Development

SLTL Group is heavily invested in research and development to stay ahead in the competitive market. Their R&D efforts focus on:

- Improving Laser Efficiency: Enhancing the efficiency of laser systems to reduce energy consumption during the scribing process.

- Developing Novel Techniques: Exploring new laser scribing techniques that could offer even greater precision and speed.

- Collaborating with Industry Leaders: Partnering with leading solar cell manufacturers to test and refine their laser systems in real-world environments.

Conclusion

Laser scribing stands out as a pivotal technology in the thin-film solar cell manufacturing industry. It offers unparalleled precision, speed, and efficiency. SLTL Group’s advanced laser systems significantly enhance the quality and performance of solar cells, making renewable energy more viable and cost-effective. By adopting SLTL’s innovative solutions, manufacturers can achieve higher efficiency, reduced costs, and superior product quality, driving the global shift towards sustainable energy.