In today’s fast-paced manufacturing world, the need for precise, durable, and efficient marking solutions is more critical than ever. Laser marking has emerged as a game-changing technology, offering unparalleled versatility for product identification and traceability. This blog explores the diverse applications, benefits, and advancements of laser marking technology, highlighting its indispensable role in various industries.

Introduction to Laser Marking

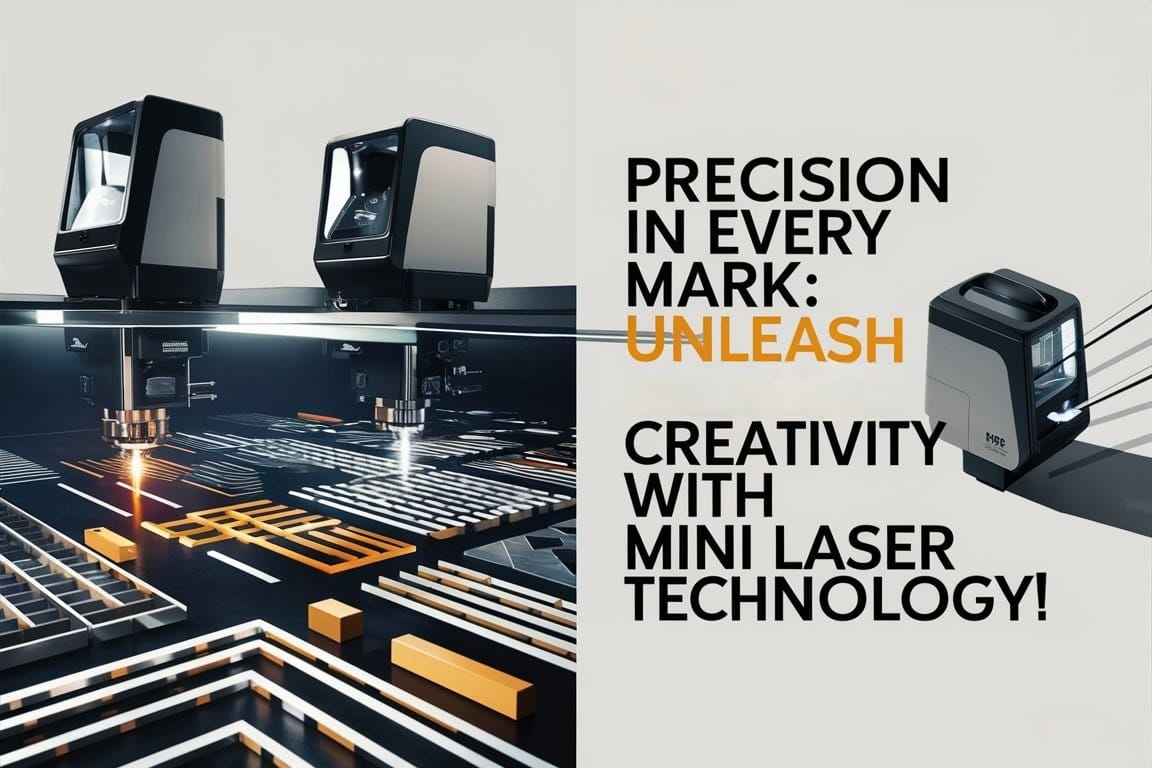

Laser marking involves using a concentrated laser beam to create permanent marks on different materials. These marks can include serial numbers, barcodes, QR codes, logos, and other identifiers essential for tracking and tracing products throughout their lifecycle. The technology’s precision and permanence make it ideal for industries where traceability, compliance, and branding are paramount.

Benefits of Laser Marking

1. Permanent and Tamper-Proof Markings

Laser marking creates permanent marks that endure throughout a product’s lifecycle. Unlike traditional labels, which can degrade or be removed, laser marks are resistant to wear, corrosion, and tampering. This durability is crucial for ensuring that traceability and identification information remains intact, even in harsh environments. Industries such as aerospace and automotive rely heavily on this feature for safety and regulatory compliance.

2. High Precision and Readability

One of the standout features of laser marking is its precision. Even intricate designs and small barcodes can be rendered with exceptional clarity. This high precision ensures that every mark is legible and scannable, reducing errors and improving operational efficiency. This is particularly important in the medical device industry, where accurate identification can be a matter of life and death.

3. Versatility Across Materials

Laser marking is incredibly versatile, capable of marking a wide range of materials, including metals, plastics, ceramics, and glass. This adaptability means manufacturers are not limited by material choice when it comes to marking. For example, metals like stainless steel and titanium can be marked using techniques such as annealing and etching, while plastics can be marked using foaming or carbonization techniques.

4. Eco-Friendly Process

In an era where environmental sustainability is a significant concern, laser marking stands out as an eco-friendly option. Unlike traditional marking methods that use inks and chemicals, laser marking is a clean process that produces no harmful emissions or waste. This makes it a responsible choice for companies looking to reduce their environmental footprint.

5. Cost-Effective in the Long Run

While the initial investment in laser marking equipment may be substantial, the long-term cost savings are significant. The technology eliminates the need for consumables like inks and labels, reducing ongoing costs. Additionally, laser marking systems require minimal maintenance, further lowering the total cost of ownership. This cost-effectiveness makes laser marking an attractive option for many manufacturers.

6. Rapid Processing Time

Laser marking is known for its speed and efficiency. Advanced laser systems can process large batches of products quickly without compromising on quality. This rapid processing capability is essential for high-volume industries such as electronics and automotive, where meeting production deadlines is critical.

Applications of Laser Marking

1. Automotive Industry

In the automotive industry, laser marking is used for marking parts with serial numbers, barcodes, and logos to ensure traceability and authenticity. This helps in tracking parts through the supply chain and supports recall management by identifying defective components quickly.

2. Medical Devices

Laser marking is indispensable in the medical sector for marking surgical instruments, implants, and medical devices with identification codes, manufacturer details, and regulatory information. The non-contact nature of laser marking ensures that the integrity of the medical devices is not compromised.

3. Electronics

In electronics manufacturing, components such as printed circuit boards (PCBs) and connectors are marked with laser technology. The precision of laser marking ensures that even the smallest components can be accurately identified, which is crucial for assembly and quality control.

4. Aerospace

The aerospace industry benefits from laser marking for the traceability of critical components. Permanent markings help in tracking parts throughout their lifecycle, ensuring safety and compliance with stringent industry standards.

Future Trends in Laser Marking

The future of laser marking is promising, with ongoing advancements making the technology even more powerful and versatile. Innovations such as shorter wavelength lasers (e.g., UV and green lasers) offer higher resolution and better contrast on various materials. Femtosecond lasers, which can mark without causing thermal damage, are ideal for sensitive applications. Additionally, the integration of AI and machine learning is enhancing the accuracy and efficiency of laser marking processes.

Conclusion

Laser marking technology has revolutionized product identification and traceability, offering unmatched precision, durability, and versatility. Its applications span numerous industries, from automotive to medical devices, ensuring products are identifiable, traceable, and compliant with regulatory standards. As technology continues to advance, laser marking will undoubtedly play an even more significant role in modern manufacturing, driving efficiency, and sustainability.

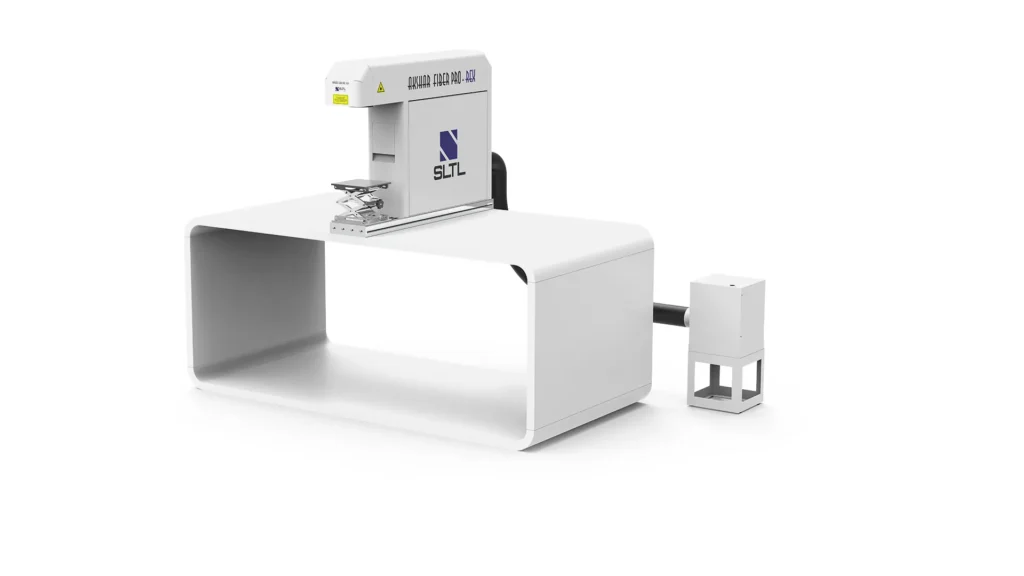

For more information on industrial laser marking solutions, explore SLTL Group’s laser marking products and learn more about their innovative technologies.